The Product Category

Background

This LCA investigates the general class of edible vegetable oils and, in particular, coconut/palm oils. Vegetable oils had gained in popularity in the latter part of the 20th century owing to dietary concerns about the high saturated fat content of animal fats like butter and that consumed in main-meal meat dishes. (18)

Producers around the world rely on a variety of plant sources such as soybean, olive, palm, sunflower, corn, cottonseed, sunflower, and rapeseed (better known as “Canola”). On the demand side, vegetable oils are used principally for frying, baking, soap, pharmaceuticals, skin lotions, mayonnaise and salad dressing. At last count, annual household consumption for a family of four amounted to around 163 lbs. for all edible uses.

Market Standing of Coconut Oil

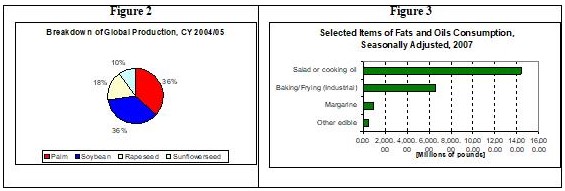

Preliminary estimates for the 2004/05 crop year showed global production of all vegetable oils at around 110 million metric tons (1). Of this, the combination of coconut and palm oil had already overtaken soybean, in large part due to organized harvesting of coconut that grows profusely and largely untended almost anywhere in tropical coastal and low-lying areas: from the Caribbean to the South Pacific, Southeast Asia, South Asia and sub-Saharan Africa.

Within the U.S., Figure 3 above shows that production into salad dressing or cooking oil accounts for nearly two-thirds of consumption of vegetable oils (2). This LCA will highlight the significant production and disposal issues associated with coconut oil. Traditional large-scale dry-process extraction, refining, bleaching and deodorizing (RBD) is energy-intensive, has high heat emissions, and calls for either hydrochloric acid or sodium hydroxide in the RBD process (3). At the consumer and institutional end-user stage, frying most foods leaves large residue volumes of burnt oil which clog drains and forms a film over the surface of waterways when not properly disposed of.

Goals and Scope

This study is patterned according to the LCA standards under ISO 14040/44 (4). In addition, this paper is consistent with three-step Society of Environmental Toxicology and Chemistry guidelines by, first of all, articulating the existing product for which improvement strategies will be investigated. Secondly, the system boundary should define the planned study depth, whether all processes and environmental effects will be accounted for (3, 7).

Given the importance of palm and coconut oils in world trade and the leading role of the product segment in U.S. domestic use, this paper undertakes a complete Life Cycle Assessment, also known as “cradle to grave” analysis (4). This means that the system boundary involves tracing the environmental impacts of coconut beginning with harvest to drying, transportation to processing mill, extraction of the oil content, packaging, distribution to point-of-sale, retailing, home or institutional use, recycling and disposal (5). The evident goal of this system boundary (see Figure 5 overleaf) is therefore that of pinpointing which of the life cycle stages bear more adverse impacts on the environment. Environmentally-conscious “best practice” and regulation can then focus on finding solutions for those stages that have the more severe impact on climate change and the environment generally.

Functional Unit

Hewing closely to the SETAC concept of a functional unit as “the system of performance which the system delivers” (7), this LCA presents the inputs and drains for a consistent unit of coconut oil. Hence, the analysis employs as a functional unit the aggregate impact of one gallon of coconut-based edible oil in home consumption. This choice of functional unit is not so much to enable a comparison with other edible oils as to assess environmental impact for a common volume benchmark at different stages of production, distribution, consumption and disposal.

The key assessment factors and environmental impact categories span a range of environmental issues consistent with the aforementioned ISO guidelines and authoritative benchmarking studies, particularly that formulated by Garrett and Collins for an unrelated product category (4, 6):

- Resource use

- Waste production and recycling

- Global warming and climate change effects

- Water pollution and freshwater/marine aquatic ecotoxicity

While the assessment is evidence-based to the maximum extent possible, the lack of regulatory oversight and, until recently, little scientific interest in the aforementioned coconut-producing regions globally means crude conditions prevail for much of the pre-processing, crushing, refining, bleaching and deodorizing stages. Nonetheless, the inventory analysis falls back on qualitative-type ratings based on the best empirical results available.

Inventory Analysis

The stages assessed in this Inventory Analysis are shown in Appendix I. First-stage production is assessed for the Philippines, historically the largest single exporter of copra (the dried form of the coconut kernel that is input for processing plants) in the world and presently the leading producer of coconut oil for the United States. The combination of high temperatures and humidity in this archipelagic nation lets coconut grow freely along all coastlines and up the hillsides until temperate elevations are reached. A total of 3.4 billion acres planted to coconut yield an estimated 12.6 billion nuts annually and 2,400 metric tons of copra equivalent, less than one-third of which is absorbed by domestic consumption (14). All told, the country exports around 848,000 MT of coconut oil.

The environmental impacts of coconut harvesting, drying to make copra, transportation to processing mill, extraction of oil content, and loading on cargo tankers plying the trans-Pacific run are therefore assessed for the Philippine context. From offloading at port of entry, trucking to packers, distribution to point-of-sale, retailing, home or institutional use, recycling and disposal, this LCA focuses on the U.S. context. Except for disposal, it is then no different from any food product or beverage retailed through grocery chains.

Since coconut (species Cocos nucifera) grows “in the wild”, requiring no special care, there are no adverse environmental impacts associated with cultivation. There being no plantation-type operations in the Philippines and since the plant is hardy, small-scale farmers apply no pesticides, herbicides or fertilizers. Hence, the threat of petrochemical run-off to drainage systems, swamps and bays is absolutely nil.

Harvesting is done manually and solely with machetes. The husk must be removed and the shell cracked to get at the inch-thick layer of coconut meat (technically, the endosperm) lining the shell. In typical operations, the coconut water that fills a significant portion of the inner hollow (about 750 ml. for a mature coconut) is simply allowed to run off. The meat is scraped out in hemispheres or sizeable segments (called “cups”) and laid on a reasonably clean surface for sun-drying. After all, the nation experiences around 8.6 hours of sunlight in summer and an average of 5.8 hours year-round.

During the rainy season, when sunlit hours are cut in half, farmers hasten the drying process by outdoor smoking: lighting slow fires fuelled by the dried husk and shells under a platform of bamboo slats with large spaces for the heat and smoke to pass through. Initially, fresh meat has a moisture content of about 60% and 27.3% of oil (16). With regular turning of the cups, moisture is cut down to about 25% at most within 24 hours.

There are no resource or emission costs for transporting copra from farm to “market” because most farmers bring the raw material to town on buffalo-drawn carts. After a proper amount has been accumulated, an open-bed cargo truck delivers copra to a wholesaler or direct to the oil mill. Here is where the first environmental impact occurs since diesel-powered and badly-maintained trucks and motor vessels are used.

At Philippine oil mills, the cups are cleared of metallic particles with rotary drum magnets, washed with water to reduce ash and mold content, and ground into coarse bits for the oil extraction process. Expeller or screw pressing is the most common method in the country’s oil mills (15). A combination of high heat, pressure and mechanical action is applied by forcing the raw material through the screw-type machine and expelling the crude oil through tiny holes on the sides of the barrel enclosure. This process removes just 75% of oil content but the pressed cake has other uses in domestic diets and as ingredient for commercial animal feeds. In operation, heat emissions owing to high pressure come to around 60° to 250° C.

All other processes from port of entry in the United States are self-explanatory. The difference is that frying with high heat causes the formation of large amounts of vapor (with entrained oil and particulate matter) that may be carcinogenic and is usually vented to the atmosphere by range hoods. After cooking, perhaps half the oil remains unabsorbed by the fried foods. Pouring used oil directly down drains causes congealing and clogged pipes, notably when the ambient temperature goes below 11°C. If the sewage system is not equipped with a septic tank, the used oil makes its way to natural bodies of water where the floating film blocks oxygenation.

Impact Analysis

In the drying stage, energy depletion is zero since farmers resort to sun-drying for most of the year and recycle coconut husks and shells for smoke-drying. Given the conversion ratio of about 20 coconuts per gallon of refined oil (the functional unit in this analysis), the combustible material from this number of nuts plus stock left over from the dry months are sufficient to bring down moisture level from the aforementioned 60% to the 6-22% that is the acceptable range for copra trading in the Philippines. It should be noted that copra traders themselves dry the stock they accumulate a bit more, on playing courts or neighboring streets, in order to get better prices at the oil mill.

We accord the global warming potential of open-pit smoking a 2.0 score on a scale of 1 to 5 only because farmers resort to this mainly at the height of the rainy season, when it is cloudy or rains all day. Otherwise, the products of combustion are just as bad as for a high-moisture wood fire (8).

For relying exclusively on petroleum-based diesel fuel, all internal transport is assigned an environmental effects score of 2.0 on the five-point scale, 0.5 for particulates, and 3.0 for the truck exhaust spewing carbon monoxide, carbon dioxide, nitrous oxide and sulfur dioxide into the atmosphere. This holds true for ocean-going vessels and at port of entry in the U.S., forklifts, tractor-trailers or trains for long-distance hauling. However, the rated values for energy depletion and global warming are qualitatively assessed somewhat lower because the equipment is both newer and better-maintained. Still, one concedes that the fuel mix for trucking remains the same.

In general, Philippine mills employ machines powered by electric motors. Since renewable sources (solar, wind, hydroelectric) account for less than 15% of the country’s power grid, “clean emissions” natural gas power plants less than 10%, and the rest of the power generation mix combines coal and bunker fuel, one must classify oil mill operations as at least a four on the five-point scale. In addition, the screw-mill expeller method emits volatile hydrocarbons and heat ranging from 66° to well in excess of 250°C, all of which is vented into the atmosphere. The Philippine manufacturing sector employs neither elevated stacks nor electrostatic precipitators because the regulatory environment is still largely concerned with automotive emissions.

Table 1: Qualitative Assessment of Impacts at Different Stages of the Coconut Oil Life Cycle (On a scale of 0 to 5 where 0 = None and 5 = Severe)

*After primary extraction, copra meal finds use in local cooking and for animal feed.

Adding to the toxicity of oil mill operations is the release of untreated effluents with dissolved solvents, alkalis, aflatoxin-contaminated soap stock, saturated bleaching mud, Fuller’s earth, activated carbon/charcoal waste, and clay.3,9

On arrival in the U.S., the more substantive environmental impacts of the product class have to do with inland transport and disposal. The cargo containers will likely be transported from port of entry to bottling plant by “tractor trailers”, running on diesel, not usually fitted with catalytic converters and therefore still spewing the same combination of greenhouse gases as when diesel-powered vehicles first roamed the interstates of America. Unhappily, “greener” alternatives like hybrid drivetrains and biofuels have yet to make headway in this vehicle class. Energy depletion for transport is a minor consideration since the fuels and lubricants used are relatively unimportant fractions when crude oil when is cracked.

Finally, one notes that at the end of the lifecycle, there are important disposal issues. As with many other liquid groceries, packaging is disposable and the polyethylene used is not biodegradable. And, as mentioned before, the burnt or food-saturated cooking oil can clog drains and form oil slicks on waterways when restaurant and residential drains lack for proper septic tanks. For the most part, used oil and burnt food solids are bagged with other food trash and disposed of in landfills. The disposal issue is easily overlooked because frying is more characteristic of ethnic cuisine (e.g. Asian-American) but not mainstream American cooking. In reality, per-capita consumption of vegetable oil is high because packaged potato chips are fried in large vats and deep frying is also used for the fried chicken and French fries so beloved of fast food patrons.1,2

Improvement Analysis

At the end of this “cradle to grave” full lifecycle assessment, one observes that the qualitatively weightiest environmental impacts occur at the processing stage. In the scale of global warming concerns, automotive emissions on Philippine roads certainly outrank the relative handful of oil mills in the nation. Nonetheless, the technology already exists to greatly reduce global warming, ecotoxicity and energy depletion at processing. One alternative is the cold wet centrifuge process, whereby fresh coconut meat and coconut water are ground into a milky solution and run through a centrifuge to separate out the oil. This has the virtues of reducing power requirements versus screw impellers (hence, lowering energy depletion rates), generating heat below 113°F/45°C (and therefore, reducing heat emissions markedly), and skipping the cleaning, refining, bleaching and deodorizing steps altogether (eliminating ecotoxity from this stage of the life cycle) (10). But there are two trade-off’s. The first is that in order to obtain the desired reductions in environmental impacts, the nation’s farm-to-market infrastructure must be so efficient that raw coconut meat can enter the plant cycle the same day the nut is dehusked and shelled (rather than the days or weeks it currently takes to produce copra as the intermediate raw material). The second is that, having skipped the deodorizing stage, the end-product has a faint but discernible coconut flavor, familiar to American nostrils as sunblock lotion or tanning oil (15).

Until the technology for biodegradable plastic bottles becomes more widespread, the workable issue at the disposal stage is what to do with that portion of 14 billion pounds of vegetable oils used annually for frying in potato chip makers and fast food restaurants. Most of the used oil is trucked to landfills and some finds its way to the “yellow oil” secondary consumer market. Since 1999, however, two researchers at the U.S. Department of Energy Idaho National Engineering and Environmental Laboratory have developed and implemented a continuous-process method to convert used frying oil to earth-friendly biodiesel fuel. The DoE-patented process produces no wastewater (unlike the 3:1 water-to-fuel ratio found in traditional operations that also drain caustic soda to the outside), burns more cleanly, produces no aromatic compounds (e.g. benzene) suspected to be carcinogenic, has a higher cetane rating (what octane is for gasoline), is rapidly biodegradable if spilled, and costs about the same as petro-diesel to produce (17). The one drawback: truck exhaust smells strongly of French fries and fried chicken.

In conclusion, this qualitative LCA has revealed that first-stage extraction and disposal bear the most adverse environmental impacts. However, technology already exists to roll back these impacts. All that is needed is a changeover in Philippine oil mills and more widespread use of the DoE technology domestically.

Appendix 1

**Volatile organic compounds

References

- US Dept. of Agriculture. Foreign Agricultural Service. Vegetable Oil Production, Consumption and Imports for Top 10 Consuming Markets. Washington, DC: 2005.

- U. S. Dept of Commerce. Economics and Statistics Administration. U.S. Census Bureau. Fats and Oils–Production, Consumption, and Stocks: 2007. Washington, DC: 2008.

- Bloemhof-Ruwaard J M, Koudijs HG, Vis JC. Environmental impacts of fat blends. Environmental and Resource Economics. 1995; 6 (4): 371-87.

- International Organisation for Standardisation (ISO). ISO 14044: Environmental management – Life cycle assessment -Requirements and guidelines. Geneve. 2006.

- Tropical Traditions, Inc. How is coconut oil produced? [Internet] 2010.

- Garrett P, Collins M. Life cycle assessment of product stewardship options for mercury-containing lamps in New Zealand: final report. Wellington (New Zealand) Ministry for the Environment; 2009.

- SETAC. Guidelines for life-cycle assessment: a code of practice, Edition 1. Workshop at Sesimbra, Portugal. 1993. P. 13.

- United States. National Research Council: Committee on Air Quality Management in the United States. Board on Environmental Studies and Toxicology. Board on Atmospheric Sciences and Climate. Division on Earth and Life Studies. Air quality management in the United States. Washington, DC: National Academies Press; 2004.

- FEDIOL. The EU Oil and proteinmeal industry: Risk analysis of the chain of coconut oil products [Internet] 2009.

- Nutiva. Coconut Oil processing chart [Internet] 2009.

- International Agency for Research on Cancer. Indoor emissions from household coal combustion carcinogenic: women in low- or medium-resource countries most exposed [Internet] 2006.

- United States. Environment Protection Agency. Emission Inventory Branch. Office of Air Quality Planning and Standards. Emission factor documentation for AP-42, Section 9.13.3: Snack chip deep fat frying, final report [Internet] 1994. Web.

- Salunkhe DK. World Oilseeds: Chemistry, Technology, and Utilization. Van Nostrand Reinhold; 1992

- Asian and Pacific Coconut Community. Country profiles: Philippines [Internet] 2010.

- Tiana Fair Trade Organics Ltd. Information on expeller pressed coconut oil [Internet] 2010

- Puertollano C, Banzon J, Steinkraus KH. Separation of oil and protein fractions in coconut. J. Agric. Food Chem. 1970, 6 (4): 579–84.

- Science Daily. New technology turns french fry oil into diesel fuel [Internet] 1999. Web.

- O’Brien, RD. Fats and Oils: Formulating and Processing for Applications. Boca Raton, FL: CRC Press; 2004.

- Gould B. Agricultural and Applied Economics. Madison, WI: UW Madison.